Ultra Light Aluminum Buckles for Hiking Backpacks

Ultra‑Light Aluminum Buckles for Hiking Backpacks

Unrivaled Strength Meets Feather‑Light Performance

In the demanding world of outdoor adventure, every gram counts—and every component matters. Your gear is an extension of your resilience, endurance, and style on the trail. Introducing our Ultra‑Light Aluminum Buckles, meticulously engineered for hiking backpacks that push boundaries without weighing you down. These buckles marry aerospace‑grade materials with precision manufacturing, delivering a product that outperforms conventional hardware in strength, durability, and weight savings.

Key Benefits

Feather‑Light Design

Each buckle weighs as little as 5 grams, allowing you to save significant pack weight over multiple closures.

Optimized geometry removes unnecessary bulk without compromising load‑bearing capacity.

Aerospace‑Grade Material

Crafted from 7075‑T6 aluminum alloy, renowned for its exceptional strength‑to‑weight ratio.

Corrosion‑resistant anodized finish withstands harsh environments and repeated exposure to moisture.

Unmatched Durability

Rated to handle loads of up to 350 kgf, exceeding the demands of fully loaded backpacks.

Fatigue‑tested for over 50,000 cycles, ensuring reliable performance on long expeditions.

Streamlined Aesthetics

Sleek, low‑profile silhouette complements modern backpack designs.

Available in multiple finishes—matte black, natural silver, and custom colors—to match any outdoor palette.

Eco‑Conscious Manufacturing

Machined with minimal waste using energy‑efficient CNC processes.

Fully recyclable at end‑of‑life, aligning with sustainable outdoor ethos.

Technical Specifications

| Feature | Specification | Benefit |

|---|---|---|

| Material | 7075‑T6 Aluminum Alloy | Superior strength and lightweight performance |

| Weight per Buckle | 5 g ± 0.2 g | Minimizes overall pack weight |

| Load Capacity | 350 kgf (771 lbs) | Exceeds standard backpack load requirements |

| Cycle Life | ≥ 50,000 fasten/unfasten cycles | Long‑term reliability on extended trips |

| Finish Options | Matte black, natural silver, custom anodized colors | Corrosion resistance & aesthetic flexibility |

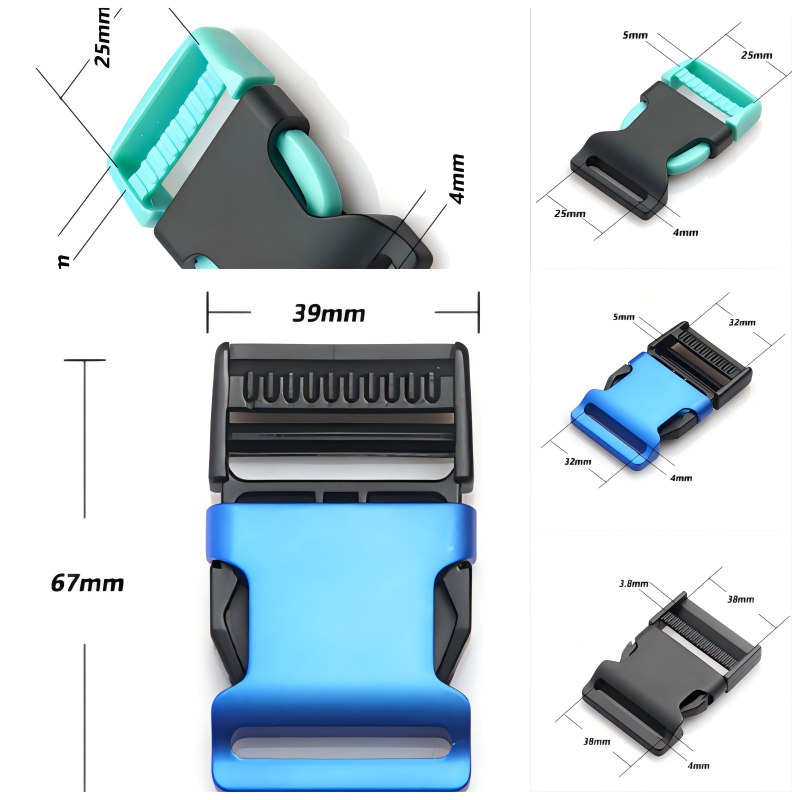

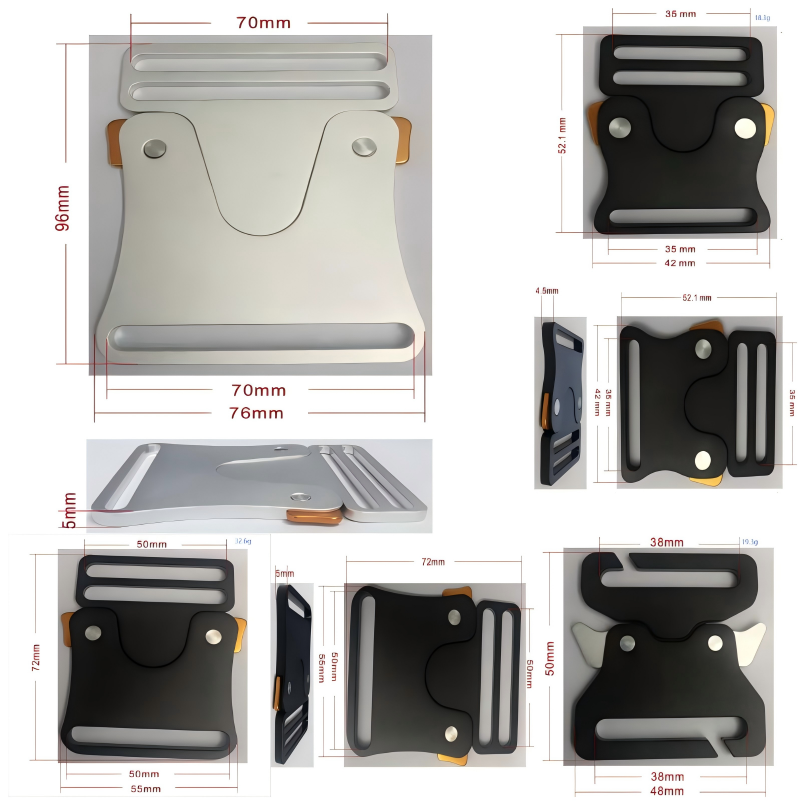

| Dimensions (mm) | 25 × 40 × 5 | Low profile to reduce snagging |

| Operating Temperature Range | –40 °C to +80 °C | Performs in extreme environments |

| Recyclability | 100% Aluminum, fully recyclable | Supports eco‑friendly gear manufacturing |

Product Lineup

| Model | Weight (g) | Load Rating (kgf) | Finish | MSRP (USD) |

|---|---|---|---|---|

| AL‑ULTRA‑25 | 5.0 | 350 | Matte Black | 3.50 |

| AL‑ULTRA‑25‑S | 5.2 | 350 | Natural Silver | 3.50 |

| AL‑ULTRA‑25‑C | 5.1 | 350 | Custom Color | 4.20 |

Ideal Applications

Daypacks & Lightweight Backpacks

Save precious grams on fast‑access pockets and compression straps.Technical Trekking & Expedition Rucksacks

Rely on hardware that holds under heavy loads and extreme conditions.Travel Luggage & Duffels

Combine strength with refined style for globetrotting gear.Mountaineering & Climbing Packs

Trusted performance when every buckle can mean the difference between stability and failure.

Why Choose Our Ultra‑Light Aluminum Buckles?

Precision Engineering

Computer‑aided design ensures each contour is optimized for maximum strength and minimum material usage.

Strict quality control at every CNC machining step guarantees consistent performance.

Rigorous Testing

Load tests conducted per ISO 9227 salt‑spray standards to simulate corrosion exposure.

Fatigue and cycle tests replicate years of outdoor use in accelerated timelines.

Seamless Integration

Retrofits effortlessly into existing strap systems—no special tools required.

Compatible with 25 mm webbing and belts, fitting the industry’s most common standards.

Custom Branding Options

Laser‑etch your logo or trail‑name onto the surface with micron‑level precision.

Select from custom anodized colors to align with brand identity or personal style.

User Testimonials

“Swapped out all my old plastic buckles for these ultra‑light aluminum versions—my pack is noticeably lighter, and they’re rock solid even in freezing rain.”

—A. Thompson, Alps Ultra‑Runner

“I never imagined a buckle could make such a difference. Minimal weight, max durability—exactly what I needed for my thru‑hike.”

—M. Rodriguez, PCT Thousand‑Miler

“Our production line loves the consistency and finish. No more breakages, and customers rave about the premium feel.”

—GearCraft Innovations, R&D Manager

Installation & Care

Strap Threading

Insert webbing through the slot, ensuring it lies flat and wrinkle‑free.

Secure with a quick double‑back stitch or heat‑seal end for professional finishes.

Routine Inspection

Periodically check for burrs or surface nicks; polish gently with a fine‑grit abrasive if needed.

Confirm load‑bearing surfaces remain free of debris to avoid premature wear.

Cleaning

Wipe with a damp cloth and mild detergent; avoid harsh chemicals that may strip anodized layers.

Dry thoroughly to maintain corrosion resistance.

Environmental & Social Responsibility

Green Manufacturing

Operated on renewable energy sources for CNC machining facilities.

Waste aluminum chips are collected and returned to smelters for closed‑loop recycling.

Community Engagement

A portion of every sale supports trail‑maintenance and Leave No Trace programs.

Partnerships with outdoor education nonprofits encourage sustainable exploration.

Ordering & Customization

Whether you’re a boutique gear shop, a large‑scale manufacturer, or an individual customization enthusiast, we cater to orders of all sizes:

| Order Quantity | Lead Time | Custom Etching Fee |

|---|---|---|

| 1–100 pcs | 3–5 business days | $0.50 per unit |

| 101–1,000 pcs | 7–10 business days | $0.30 per unit |

| 1,001+ pcs | 14–21 business days | Negotiable |

Contact us at sales@yourbrand.com for a personalized quote, sample requests, or technical drawings.

Conclusion

Embrace the next generation of backpack hardware with our Ultra‑Light Aluminum Buckles—where every detail is thoughtfully engineered to surpass the challenges of the trail. From the meticulous selection of aerospace‑grade materials to the precision of CNC machining and the depth of our environmental commitments, we deliver hardware that stands as a hallmark of quality, performance, and sustainability.

Redefine your gear. Lighten your load. Elevate your adventure.