Mushroom Rivets, Flat Head Rivets and Solid Rivets

Mushroom Rivets, Flat Head Rivets, and Solid Rivets: Essential Hardware for Durability and Style

Rivets have long been essential fasteners in various industries, offering secure, durable joining solutions that withstand stress and wear. Among them, mushroom rivets, flat head rivets, and solid rivets are especially valued for their unique structures, aesthetic versatility, and robust functionality. From bags and leather goods to industrial applications, these rivets serve as reliable connectors that enhance both strength and style. Below, we explore the features and advantages of each type, along with popular uses that showcase their importance across different products and projects.

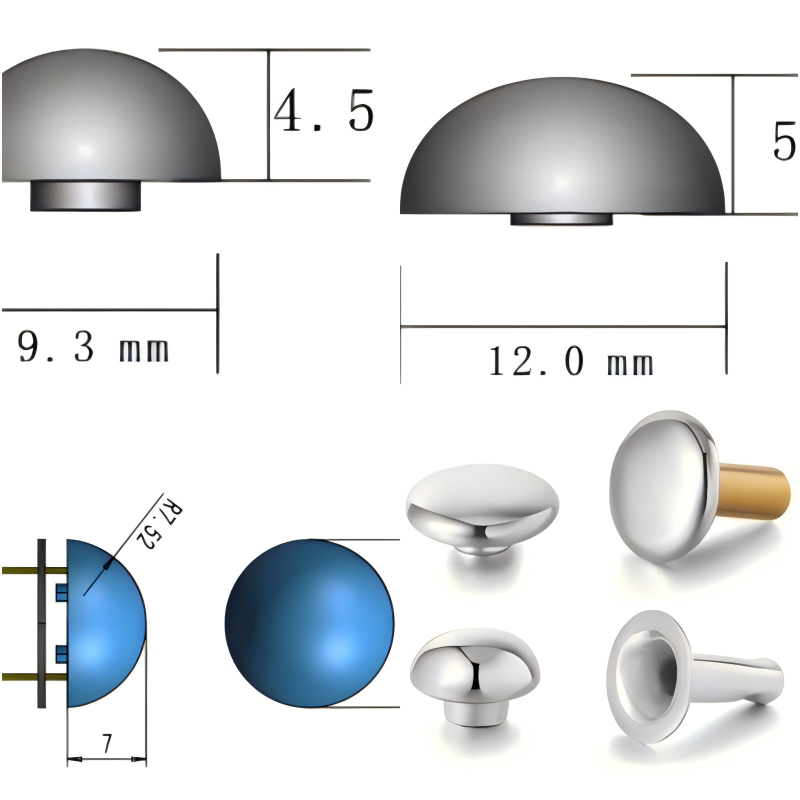

Mushroom Rivets: A Blend of Style and Strength

Mushroom rivets, named for their rounded, dome-like heads, are highly favored for both their durability and aesthetic appeal. The mushroom shape not only provides added support for heavier materials but also creates a smooth, rounded finish that complements the look of many products. These rivets are commonly seen in fashion accessories, leather goods, and high-quality bags, where durability and appearance are equally important.

Key Advantages:

Enhanced Load Distribution: The rounded shape of mushroom rivets allows them to distribute load evenly, making them ideal for securing layers of fabric, leather, or other durable materials.

Aesthetic Versatility: Mushroom rivets add a decorative touch to leather goods, bags, and other items where a finished look matters.

Durability in High-Stress Applications: Built to withstand pressure, mushroom rivets perform well in items that experience frequent handling or movement, such as luggage and belts.

Common Uses: Mushroom rivets are popular in fashion bags, leather accessories, wallets, and industrial equipment where both function and style are priorities.

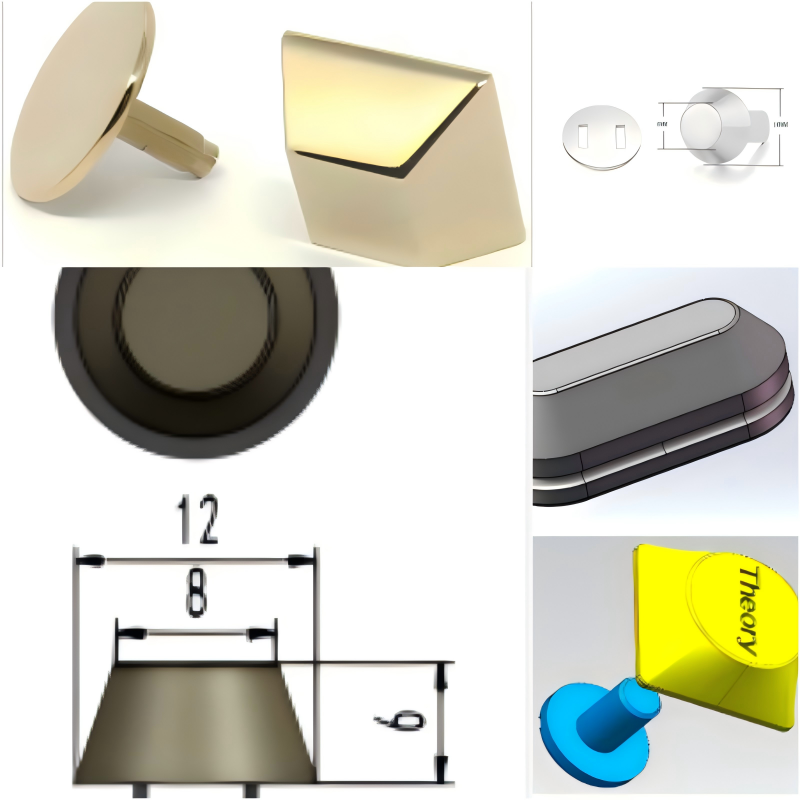

Flat Head Rivets: Sleek and Subtle with a Low-Profile Finish

Flat head rivets are known for their flat, unobtrusive heads that sit flush with the material surface. This low-profile design minimizes snagging and offers a clean, streamlined appearance, making flat head rivets a preferred choice for applications where a smooth surface is essential. These rivets are commonly used in the construction of bags, belts, and even machinery that requires smooth edges.

Key Advantages:

Streamlined Appearance: The flat head ensures a neat, flush finish, contributing to a clean, professional look.

Minimized Snagging: With a smooth surface, flat head rivets reduce the risk of snagging on fabric or other materials, ideal for clothing and accessories.

High Shear Strength: Despite their low profile, flat head rivets provide excellent shear strength, making them suitable for holding together multiple layers of material securely.

Common Uses: Flat head rivets are frequently used in handbags, wallets, straps, and machinery where both strength and a smooth finish are critical.

Solid Rivets: Unmatched Durability and Dependability

Solid rivets are a staple in heavy-duty applications where extreme durability and reliability are required. Unlike hollow rivets, solid rivets consist of a single, solid piece that creates a permanent, tamper-proof bond when installed. These rivets are widely used in industries that demand structural integrity, such as automotive, aerospace, and leatherworking for heavy-duty bags and cases.

Key Advantages:

Superior Strength: Solid rivets offer the highest level of strength and durability among rivet types, ideal for high-stress applications.

Permanent Bond: Once installed, solid rivets create a secure, permanent bond, providing added security for applications that cannot afford to have components come apart.

Resilience to Vibration and Impact: Due to their solid structure, these rivets are highly resistant to vibration and impact, making them well-suited for machinery, vehicles, and industrial equipment.

Common Uses: Solid rivets are frequently utilized in manufacturing for automotive and aerospace applications, as well as in the construction of heavy-duty leather goods, backpacks, and tool belts.

Choosing the Right Rivet for Your Needs

The decision between mushroom, flat head, and solid rivets depends on the specific demands of the project. Each rivet type offers unique strengths, making them suited to different applications:

Mushroom Rivets: Ideal for items that need both strength and a decorative touch, such as leather goods and fashion accessories.

Flat Head Rivets: Best for applications that require a sleek, flush surface and minimal snagging, common in bags, straps, and garments.

Solid Rivets: The go-to choice for heavy-duty applications where maximum durability and a permanent bond are essential.

Conclusion: The Importance of Quality Rivets

From adding aesthetic value to ensuring structural integrity, quality rivets are essential components in both fashion and industrial applications. Mushroom rivets, flat head rivets, and solid rivets each bring their own set of benefits, providing solutions that cater to a wide range of functional and aesthetic needs. Whether you’re looking for a rivet that enhances the look of leather goods or one that will withstand the test of time in high-stress environments, selecting the right rivet type can make all the difference in your project’s success.