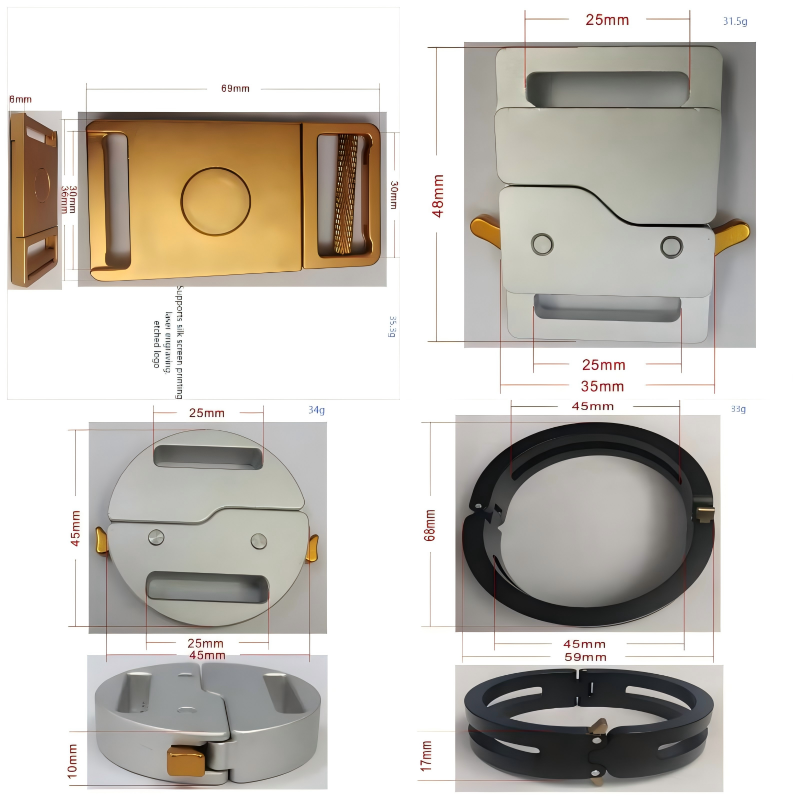

Anodized Military and Mountaineering Aluminum Alloy Buckles

Anodized Military and Mountaineering Aluminum Alloy Buckles: Strength, Durability, and Versatility

In both military operations and mountaineering adventures, gear reliability is paramount. Among the essential components that contribute to the functionality and safety of equipment are aluminum alloy buckles. These buckles, particularly those made from anodized aluminum alloy, offer a blend of strength, durability, and lightweight performance, making them indispensable in the most demanding environments. Whether used in tactical gear, climbing harnesses, or outdoor equipment, these buckles ensure secure fastening, quick release, and long-lasting resilience.

This article delves into the significance of anodized military and mountaineering aluminum alloy buckles, focusing on their key features, benefits, and applications across various outdoor and tactical fields.

Why Aluminum Alloy?

Aluminum alloy is a popular material for buckles due to its remarkable properties, combining strength and lightness. This makes it ideal for applications where weight needs to be minimized without compromising durability.

Aluminum alloys are corrosion-resistant, a crucial factor when buckles are exposed to harsh outdoor conditions such as rain, humidity, or salty environments. The alloy’s inherent strength also allows it to withstand substantial force and pressure, making it a reliable material for military and mountaineering purposes.

The Benefits of Anodizing

Anodizing is an electrochemical process that increases the natural oxide layer on the surface of aluminum, enhancing its resistance to wear and corrosion. Anodized aluminum buckles are not only more durable but also offer an aesthetically pleasing, smooth finish. The process allows for color customization, which is a bonus for military and tactical uses where different finishes may be needed for camouflage or coordination with other gear.

The anodized layer acts as a protective barrier, preventing the buckle from corroding or wearing out even in the most extreme conditions. This makes anodized buckles suitable for long-term use in environments that would quickly degrade other materials.

Applications of Anodized Aluminum Alloy Buckles

1. Military Gear

In military settings, anodized aluminum alloy buckles are frequently used in a variety of gear, including tactical vests, belts, backpacks, and harness systems. These buckles provide the reliability needed in high-stress situations, where equipment failure is not an option.

Quick-release systems: In combat, speed is critical. Quick-release buckles made from anodized aluminum allow soldiers to fasten or unfasten gear swiftly, ensuring that they can react quickly in emergencies. The lightweight nature of aluminum also ensures that soldiers can carry heavy loads without adding unnecessary weight to their gear.

Camouflage and stealth: Anodizing allows for a range of colors, which is beneficial in creating buckles that match various military environments, from desert terrains to dense forests. The non-reflective finish of anodized buckles also ensures that they do not give away a soldier's position due to unwanted glare.

2. Mountaineering Equipment

Mountaineering demands equipment that can withstand extreme stress, weight, and environmental factors. Aluminum alloy buckles are often used in climbing harnesses, backpacks, and safety straps, ensuring that climbers remain secure in precarious situations.

High load-bearing capacity: Anodized aluminum buckles are designed to handle significant weight, making them ideal for use in climbing gear where the risk of failure can lead to life-threatening situations. Their ability to resist deformation under load makes them a preferred choice for mountaineers.

Weather resistance: Climbers often face harsh weather conditions, including rain, snow, and intense UV exposure. Anodized aluminum buckles are corrosion-resistant, ensuring that even after prolonged exposure to the elements, they maintain their structural integrity.

3. Outdoor Adventure Gear

From camping gear to hiking backpacks, aluminum alloy buckles are ubiquitous in outdoor adventure equipment. Their durability and lightweight nature make them ideal for activities where gear must be both functional and portable.

Backpacks and straps: Buckles play a critical role in the adjustment and securement of straps on backpacks and outdoor gear. Anodized aluminum buckles are not only strong but also lightweight, ensuring that outdoor enthusiasts can carry their gear comfortably without compromising on safety.

Tents and shelters: For securing tents, tarps, and shelters, anodized aluminum buckles provide a reliable fastening mechanism that can handle tension and weight, even in high winds or adverse weather conditions.

Durability in Extreme Conditions

One of the standout features of anodized aluminum alloy buckles is their durability in extreme conditions. Whether exposed to saltwater, freezing temperatures, or intense sunlight, these buckles are built to last. The anodized coating offers enhanced protection against corrosion, wear, and UV damage, ensuring that the buckle's performance remains consistent even after extended use in harsh environments.

Saltwater resistance: For gear used in marine environments or by military personnel operating near coastal areas, corrosion from saltwater is a constant concern. Anodized aluminum buckles resist rusting and corrosion, ensuring longevity and reliability in these conditions.

Temperature tolerance: Both high and low temperatures can degrade certain materials over time. Anodized aluminum buckles are designed to function across a broad range of temperatures without losing strength or functionality, making them suitable for use in both hot deserts and icy mountain ranges.

Lightweight, Yet Strong

One of the key advantages of using aluminum alloy buckles is their superior strength-to-weight ratio. In tactical and mountaineering applications, every ounce of weight matters. Anodized aluminum buckles offer exceptional strength while remaining lightweight, ensuring that they don’t weigh down the user or the equipment.

For instance, mountaineers who must carry heavy gear for long distances or at high altitudes benefit significantly from the lightweight properties of aluminum alloy buckles. Similarly, military personnel, who often carry a significant load of equipment, appreciate the reduced weight without sacrificing durability or performance.

Customization and Versatility

Another advantage of anodized aluminum buckles is the ability to customize their appearance and functionality. Anodizing allows manufacturers to apply a variety of colors, which can be used for coding or simply to match the aesthetic of specific gear. This is particularly useful in the military, where different units may require different gear configurations, or in outdoor adventure products where color coordination can enhance brand appeal.

Moreover, the versatility of anodized aluminum buckles makes them suitable for a wide range of applications beyond just military and mountaineering. They are also commonly used in:

Safety equipment

Paragliding gear

Camping and outdoor accessories

Conclusion

Anodized military and mountaineering aluminum alloy buckles are essential components in ensuring the reliability and safety of outdoor and tactical gear. Their combination of strength, durability, and lightweight properties makes them ideal for extreme environments, from the battlefield to the mountainside.

Whether used in quick-release systems for military personnel or in climbing harnesses for mountaineers, these buckles provide the secure fastening and ease of use required in critical situations. With their resistance to corrosion, wear, and environmental damage, anodized aluminum buckles are built to last, ensuring that they remain a trusted element of tactical and outdoor gear for years to come.