How is the production of a Nipple Rivet and about Nipple Rivet,Stud Rivet,Decorative Rivet,Round Head Rivet,Mushroom Rivet

Nipple Rivet, Stud Rivet, Decorative Rivet, Round Head Rivet, and Mushroom Rivet are essential components for various applications, each offering unique advantages. Nipple Rivets are ideal for adding both functionality and a sleek, rounded aesthetic to bags and leather goods, providing secure fastening with a subtle design. Stud Rivets, with their pronounced protrusions, are perfect for creating bold accents on clothing, footwear, and accessories, giving products a rugged, edgy look. Decorative Rivets excel in enhancing the visual appeal of garments, shoes, and bags, offering diverse shapes and styles that add flair and individuality. Round Head Rivets are known for their sturdy design, often used in industrial and construction applications where reliable fastening is crucial, ensuring components stay securely in place. Mushroom Rivets, with their distinctive cap-like heads, serve both decorative and practical purposes, making them suitable for a wide range of fashion and utility items where a balance of form and function is required. Each rivet type contributes to the durability and style of the products they are used in, making them indispensable in various industries.

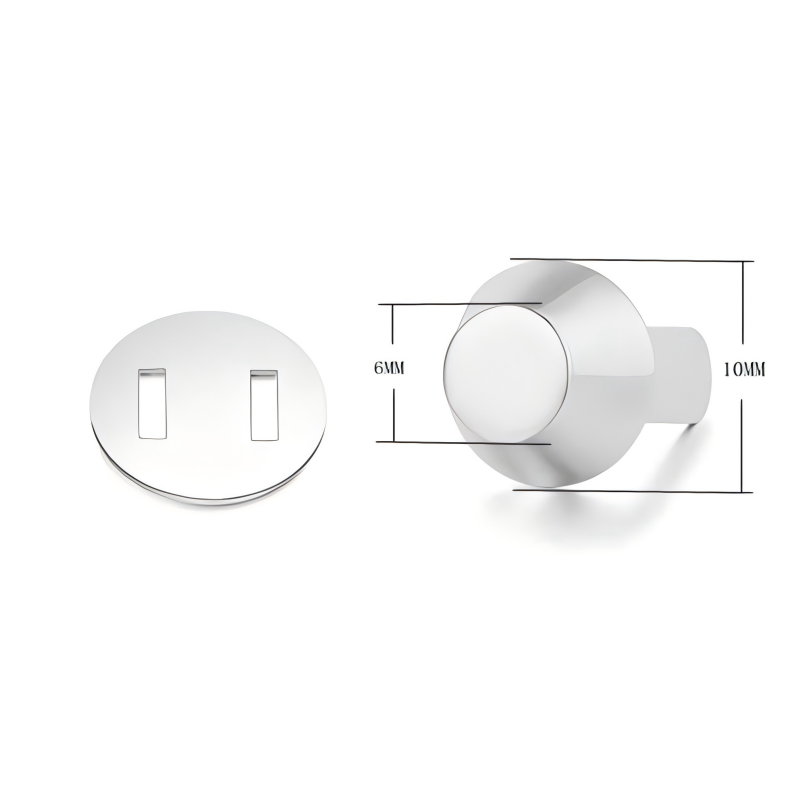

The production of a Nipple Rivet involves several meticulous steps, each crucial to ensuring the rivet’s strength, durability, and aesthetic appeal. The process begins with material selection, where high-quality metals such as brass, steel, or aluminum are chosen based on the desired application and finish. The selected metal is then cut and shaped into small cylindrical blanks, which will eventually form the body of the rivet.

Next, the blanks undergo a cold forming process, where they are pressed into the distinctive nipple shape using a series of dies and punches. This step is critical, as it shapes both the head and shank of the rivet, giving it the iconic rounded top that provides a smooth finish once installed. Trimming and deburring follow, where excess material is removed, and rough edges are smoothed to ensure a clean and polished appearance.

After forming, the Nipple Rivet may undergo additional processes such as heat treatment to enhance its strength or plating and coating to add a protective layer that resists corrosion and enhances the visual appeal. The rivets are then subjected to rigorous quality control checks to ensure they meet strict standards for size, shape, and durability.

Finally, the Nipple Rivets are packaged and prepared for distribution, ready to be used in various applications where both functionality and design are paramount, such as in bags, leather goods, and fashion accessories.