Heavy Duty Straps and Buckles

Heavy Duty Straps and Buckles: Ultimate Strength for Every Challenge

When it comes to securing your most valuable cargo, whether it’s heavy equipment on an industrial site, luggage on an adventure-packed road trip, or critical components on a rescue harness, there’s no room for compromise. Our Heavy Duty Straps and Buckles are meticulously engineered to deliver unparalleled strength, reliability, and versatility. From raw materials to final inspection, every step of our production process is optimized to ensure that you experience consistent performance in the most demanding environments.

Uncompromising Materials: Built for Endurance

At the core of every strap and buckle assembly is the material itself. We select only premium-grade synthetic fibers—such as 1000-denier nylon and high-tenacity polyester—that are woven with precision to deliver an optimal balance of tensile strength, abrasion resistance, and flexibility. These fibers undergo rigorous quality control tests, including tensile testing to verify break strengths well above industry standards, and UV exposure trials to ensure long-lasting colorfastness and structural integrity under direct sunlight.

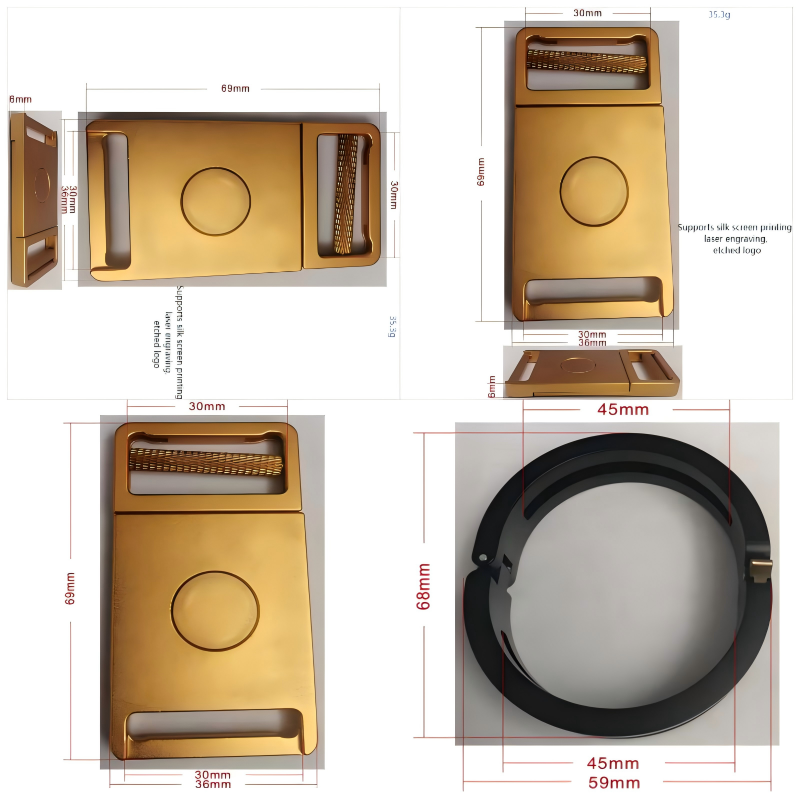

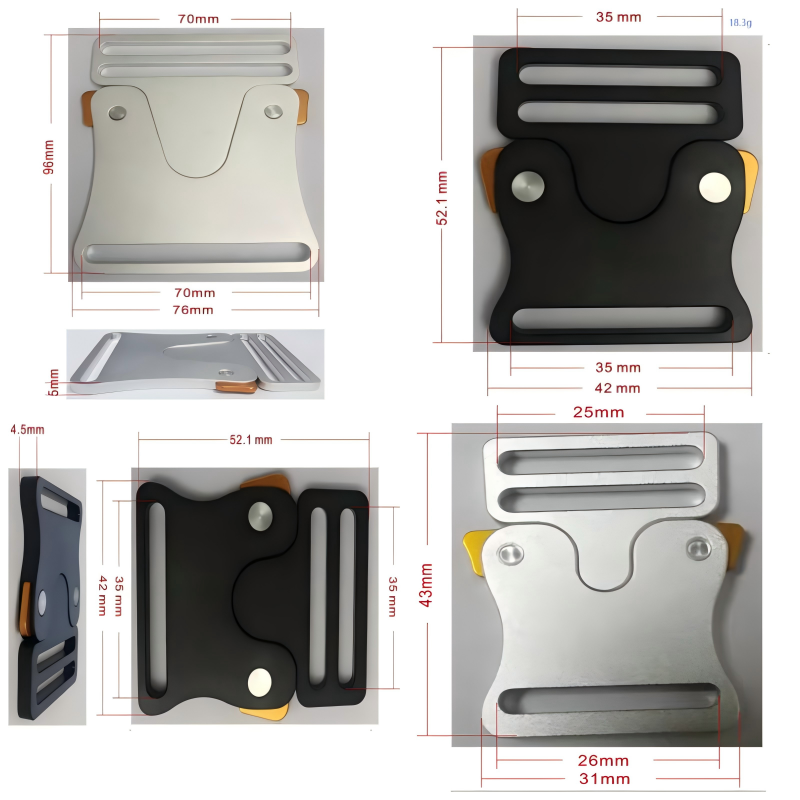

Similarly, our buckles are crafted from aerospace-grade aluminum alloys or high-strength stainless steel, chosen for their exceptional combination of light weight and corrosion resistance. Each metal component is cast or forged under tightly controlled conditions, then CNC-machined to achieve exacting tolerances. After machining, our buckles undergo an advanced anodizing or passivation process to create a durable surface finish that resists scratches, salt spray, and chemical exposure. The result? A product that looks as good as it performs, season after season.

Innovative Design: Precision Meets Practicality

Strength alone is not enough; a truly exceptional strap-and-buckle system must also be intuitive and user-friendly. That’s why our design team focuses on ergonomic features that streamline installation and adjustment:

Quick-Release Mechanism: With a single-handed push-button action, you can rapidly release tension without fumbling, even while wearing gloves.

Micro-Adjust Ratchet: Fine-tune your strap length to within millimeters for a snug, secure fit that won’t slip under load.

Anti-Twist Webbing Channel: Our buckle slots are chamfered and beveled to guide the webbing straight, preventing twisting and ensuring even load distribution.

Integrated Locking Tab: For high-vibration applications, an additional locking tab snaps into place, guaranteeing the buckle remains closed under extreme conditions.

These design elements are the culmination of intensive field trials, laboratory simulations, and direct feedback from professionals who demand nothing but the best.

Performance You Can Measure: Technical Specifications

To help you select the perfect model for your application, we’ve compiled a detailed specification chart. All dimensions are given in millimeters (mm), and load capacities denote safe working loads (SWL).

| Model Reference | Strap Width (mm) | Buckle Length × Width (mm) | Safe Working Load (kg) | Material Combination |

|---|---|---|---|---|

| HD-25-AA | 25 | 60 × 38 | 500 | Nylon 1000D + Alloy 6061-T6 Anodized Aluminum |

| HD-38-SS | 38 | 75 × 45 | 800 | Polyester 1200D + 304 Stainless Steel |

| HD-50-AA | 50 | 90 × 55 | 1200 | Nylon 1200D + Alloy 6061-T6 Anodized Aluminum |

| HD-75-SS | 75 | 110 × 70 | 2000 | Polyester 1500D + 316 Stainless Steel |

| HD-100-AA | 100 | 130 × 85 | 3000 | Nylon 2000D + Alloy 6061-T6 Anodized Aluminum |

| HD-150-SS | 150 | 150 × 100 | 5000 | Polyester 2000D + 316 Stainless Steel |

Real-World Applications: Versatility in Action

Industrial Logistics and Freight

In warehouses, shipping yards, and on flatbed trucks, securing pallets and heavy machinery is critical to preventing costly accidents and downtime. Our HD straps and buckles are rated to exceed the rigorous demands of ISO 9001-certified operations, ensuring that forklifts, cranes, and automated handling systems operate safely and smoothly.

Outdoor Recreation and Adventure Sports

Whether you’re rock climbing, white-water rafting, or embarking on a cross-country bike tour, reliable gear could mean the difference between success and disaster. Our straps resist abrasion from rocky surfaces, while buckles deliver rock-solid performance even after repeated exposure to rain, mud, and saltwater.

Emergency Response and Rescue Operations

First responders trust equipment that never fails. Our harness straps and quick-release buckles have been adopted by search-and-rescue teams and fire departments for their life-grade performance under extreme stress. Ergonomic release tabs allow rescuers to free victims quickly, reducing rescue times and improving outcomes.

Military and Tactical Gear

Durability under pressure is a non-negotiable requirement in defense applications. Our NATO-compatible straps and buckles are built to withstand shock, vibration, and exposure to harsh chemicals—ensuring consistent performance in the most demanding theaters of operation.

Quality Assurance: Rigorous Testing at Every Turn

From raw material inspection to final assembly, our quality management system leaves nothing to chance. Key stages include:

Incoming Material Verification: Chemical and mechanical property analysis of metal billets; denier and tensile testing of synthetic fibers.

In-Process Dimensional Checks: Laser micrometry ensures every buckleSlot and ratchet tooth meets design tolerances of ±0.05 mm.

Load and Fatigue Testing: Hydraulic pull machines simulate repeated tension cycles to guarantee no slippage or deformation up to ten times the SWL.

Environmental Stress Screening: Combined salt-spray, UV, and temperature cycling to replicate years of outdoor exposure within days.

Final Functional Review: Hand-checked click, release, and adjust operations assessed by certified inspectors before packaging.

All test results are logged and traceable via serialized batch numbers, giving you full visibility into the history and performance of each unit.

Customization Options: Tailored to Your Needs

Our manufacturing flexibility allows for bespoke solutions, including:

Color Coding: Choose from a full Pantone spectrum for easy identification in multi-strap configurations.

Branding Plates: CNC-etched logo plates or laser-engraved surfaces deliver a premium aesthetic.

Variable Lengths: From 0.5 meters to over 10 meters per strap, cut to precise lengths on demand.

Combination Assemblies: Pair straps with hooks, clamps, or mesh payload carriers for turnkey load-securing kits.

Whether you need a one-off prototype or a full production run, our skilled engineering team can collaborate on design, material selection, and performance targets to meet your exact specifications.

Sustainability Commitment: Durability That Lasts

Designed for longevity, our heavy duty straps and buckles help reduce waste by outliving lower-grade alternatives. Moreover, we incorporate eco-friendly practices:

Recycled Materials: Optionally integrate post-consumer recycled polyester in webbing while maintaining mechanical properties.

Low-VOC Coatings: Anodizing and passivation processes use low-emission chemicals that comply with RoHS and REACH standards.

Waste Reduction: Closed-loop water filtration during finishing stages minimizes wastewater volume and toxicity.

By choosing our products, you’re investing in solutions that protect both your assets and the planet.

Installation and Maintenance: Easy, Efficient, Essential

Brake pads don’t need replacing, but your straps and buckles sometimes do. To ensure ongoing reliability:

Regular Inspection: Look for frayed fibers, corrosion spots, or deformation in buckle jaws every 6 months or after heavy use.

Cleaning: Mild soap and water clean webbing; metal parts can be wiped with isopropyl alcohol to remove grease or contaminants.

Storage: Store in a dry, shaded environment at ambient temperatures. Avoid prolonged exposure to direct sunlight or harsh chemicals.

Replacement Guidelines: Replace straps at the first sign of welding-through or reduction in rated thickness, and buckles if any mechanical play or slippage is detected.

Following these simple steps will extend the service life of your equipment and ensure safety remains uncompromised.

Why Choose Our Heavy Duty Straps and Buckles?

Unmatched Strength: Industry-leading SWL ratings tested well beyond normal use cases.

Precision Engineering: Tight tolerances and superior finish for ease of use.

Proven Reliability: Field-tested across sectors from marine transport to aerospace.

Customizable: Engineering support for prototypes and high-volume needs.

Sustainable Practices: Materials and processes that reduce environmental impact.

Join thousands of customers worldwide who trust our heavy duty straps and buckles to secure what matters most. Whether you’re hauling, lifting, or life-saving, our products deliver the confidence you need to focus on the task at hand—knowing your load is locked down.

Contact us today to discuss your application requirements and discover why our heavy duty straps and buckles set the standard for strength, safety, and durability.