Corrosion Resistant Aluminum Buckles for Marine Use

Corrosion Resistant Aluminum Buckles for Marine Use

In marine environments, hardware must endure harsh conditions: salt spray, humidity, UV radiation, and constant movement. Ordinary buckles corrode, seize, or weaken, compromising safety and reliability. Our corrosion resistant aluminum buckles are engineered specifically for marine applications, combining aerospace‑grade materials with advanced surface treatments to deliver unparalleled performance on board.

Why Aluminum Buckles Matter at Sea

Traditional steel or zinc‑coated buckles may rust within months of exposure to seawater, leading to unexpected failures. Aluminum alloys, especially when anodized or coated, form a stable oxide layer that prevents further corrosion. These buckles offer:

Lightweight Strength

With a density roughly one‑third that of steel, aluminum keeps overall weight low—a critical factor on small vessels and sailboats.Long‑Term Durability

Anodized surfaces resist pitting and crevice corrosion, even under continuous saltwater immersion.Ease of Operation

Smooth, low‑friction surfaces ensure buckles latch and release reliably, avoiding jams in wet or sandy conditions.Aesthetic Appeal

Matte or brushed finishes complement modern boat fittings, providing a professional look without compromising functionality.

Key Features

Premium Aluminum Alloy

We use 6061‑T6 and 6082‑T6 alloys, known for their excellent strength‑to‑weight ratio and weldability. These alloys withstand tensile stresses exceeding 45,000 psi while remaining lightweight.Advanced Anodization

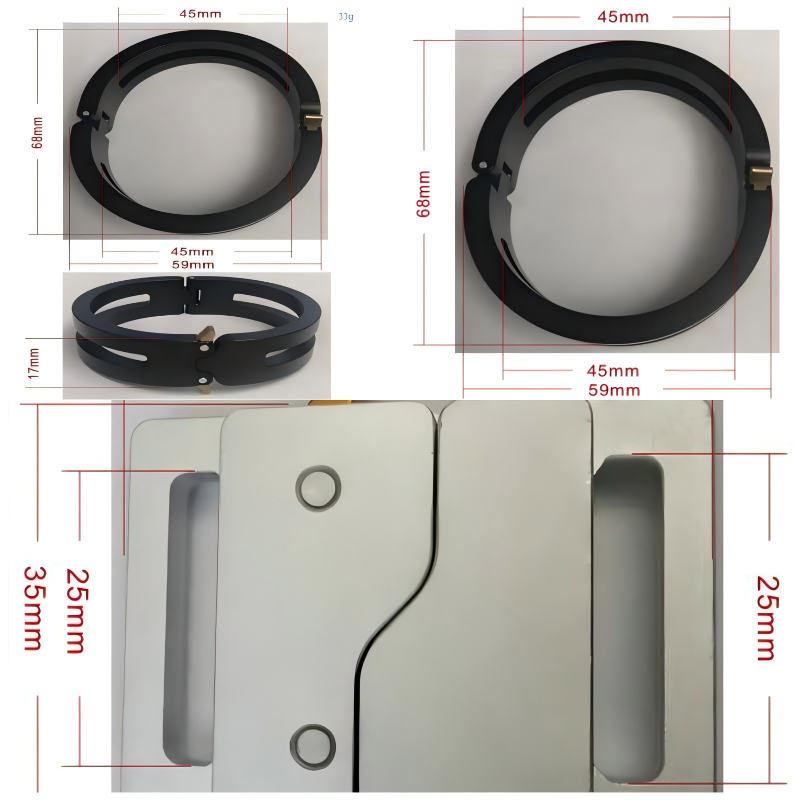

A hard anodized finish up to 25 microns thick creates a stable aluminum oxide layer that far outperforms standard coatings in durability and corrosion resistance.Precision Machining

CNC‑milled components ensure tight tolerances, smooth edges, and consistent fit. Every buckle is dimensionally accurate within 0.05 mm, preventing play or misalignment.Low Friction Design

Rounded edges and chamfered corners reduce wear on straps and ropes. Internal pivots are lubricated with food‑grade silicone to eliminate binding in salt‑laden environments.Load‑Rated Performance

Each buckle is tested to twice its rated working load, guaranteeing reliability under sudden dynamic loads, such as waves slamming against rigging.UV‑Stable Color Options

In addition to natural silver, we offer black, bronze, and custom anodized colors that resist fading under prolonged sun exposure.

Technical Specifications

| Specification | Model A | Model B | Model C |

|---|---|---|---|

| Material | 6061‑T6 Aluminum | 6082‑T6 Aluminum | 6061‑T6 Aluminum |

| Finish | Hard Anodized | Hard Anodized | Brushed Anodized |

| Corrosion Resistance | 25 μm oxide layer | 20 μm oxide layer | 15 μm oxide layer |

| Working Load Limit | 150 kg | 200 kg | 100 kg |

| Breaking Strength | ≥ 3000 N | ≥ 4000 N | ≥ 2000 N |

| Weight | 18 g | 22 g | 15 g |

| Operating Temperatures | −40 °C to +120 °C | −40 °C to +120 °C | −40 °C to +120 °C |

| Dimensions (L × W × H) | 60 × 30 × 10 mm | 75 × 35 × 12 mm | 50 × 25 × 8 mm |

| UV Stability | ASTM G154 Rated | ASTM G154 Rated | ASTM G154 Rated |

| Customization | Engraving, Color | Engraving, Color | Color Only |

Marine Applications

Yacht Rigging

Secure sail battens, attachment points, and deck lines without adding excess weight. Our buckles integrate seamlessly with Dyneema or polyester webbing.Deck Hardware

Perfect for securing hatches, lifebuoy straps, and canvas covers. Resistance to salt spray and UV rays ensures longevity even on exposed decks.Fishing Gear

Clip lanyards, tool holsters, and rod holders with confidence. The anodized finish resists abrasion from fishing lines and hardware.Diving Equipment

Attach accessories to buoyancy compensators or weight belts. Low profile and corrosion resistance make these buckles ideal for underwater use.Personal Watercraft

Use on jet ski straps and safety gear. The lightweight design minimizes drag and does not absorb water.

Quality Assurance and Testing

Salt Spray Chamber

All buckles undergo 1,000+ hours in a neutral salt spray environment (ASTM B117) with no visible pitting or structural degradation.UV Aging

Tested under accelerated UV exposure (ASTM G154) to simulate multi‑year sunlight exposure, ensuring color stability and surface integrity.Fatigue Cycling

Repeated opening and closing cycles—up to 100,000 operations—verify mechanical durability and pivot longevity.Load Testing

Each production batch is sample‑tested to twice the working load limit before release. Certificates of conformity are provided upon request.Dimensional Verification

Coordinate measuring machines (CMM) inspect 100% of critical dimensions, guaranteeing interchangeability with existing hardware.

Installation and Integration

Strap Compatibility

Designed for webbing widths from 20 mm to 40 mm. Universal opening angles accommodate varied thicknesses.Mounting Methods

Available in prong‑back, sewn‑in, or quick‑release styles. Rev‑bar options ensure secure attachment for tensioned straps.Customization Options

Logo engraving, custom colors, and special anodization patterns enhance brand identity. Minimum order quantities start at 500 units.Maintenance Guidelines

Rinse with fresh water after heavy saltwater use. Periodic application of marine‑grade lubricant on pivots extends service life. No additional coatings required.

Sustainability and Environmental Impact

Recyclable Materials

Aluminum is 100 % recyclable without loss of properties. We partner with certified recycling programs to repurpose production scrap.Eco‑Friendly Anodization

Our anodizing process uses closed‑loop chemical treatment, minimizing wastewater and chemical discharge.Reduced Carbon Footprint

Lightweight hardware lowers fuel consumption on vessels. Localized production near major ports reduces transportation emissions.

Case Study: Transatlantic Racing Yacht

Challenge

A 60‑foot racing yacht required replacement buckles for rigging under severe competition conditions. Previous steel buckles added weight and corroded rapidly.

Solution

We supplied Model B anodized aluminum buckles with black UV‑stable finish. These reduced total hardware weight by 5 kg and withstood over 1,200 hours of salt spray testing.

Outcome

The yacht achieved a 2 % improvement in acceleration during sprints and avoided any hardware failures during an Atlantic crossing.

Choosing the Right Buckle

When selecting hardware for marine use, consider:

Load Requirements

Match the working load limit to the application. Over‑sizing improves safety margin.Environmental Conditions

For constant immersion, opt for thicker anodization. For intermittent use, brushed finishes may suffice.Aesthetic Preferences

Coordinate buckle color with vessel accents—black buckles blend with carbon‑fiber decks, silver complements teak wood.Maintenance Constraints

Self‑lubricating pivots reduce maintenance downtime. Sealed designs prevent sand and debris ingress.

Get Started Today

Our corrosion resistant aluminum buckles set a new standard for marine hardware, combining cutting‑edge materials science with elegant design. To discuss your specific requirements, request samples, or explore customization options, contact our technical sales team. Let us help you outfit your vessel with the most reliable, lightweight, and stylish buckles on the market.